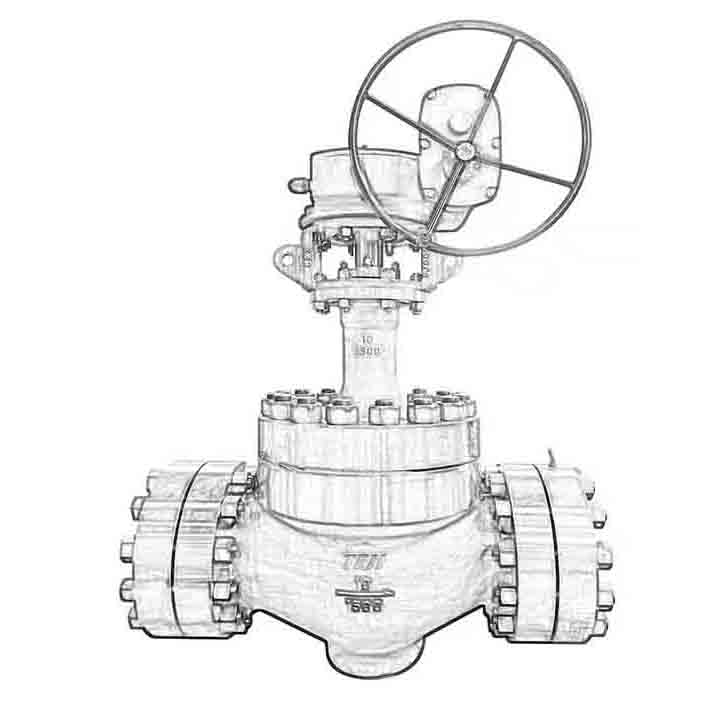

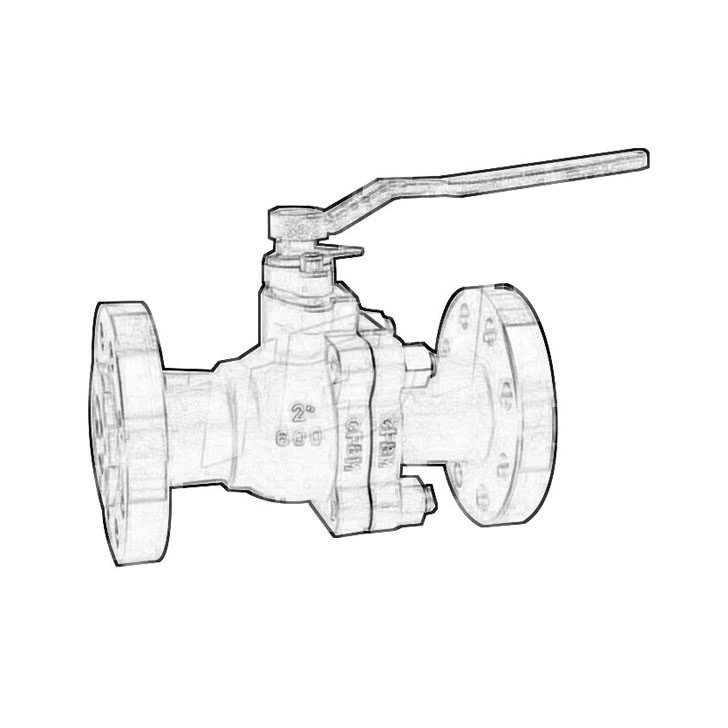

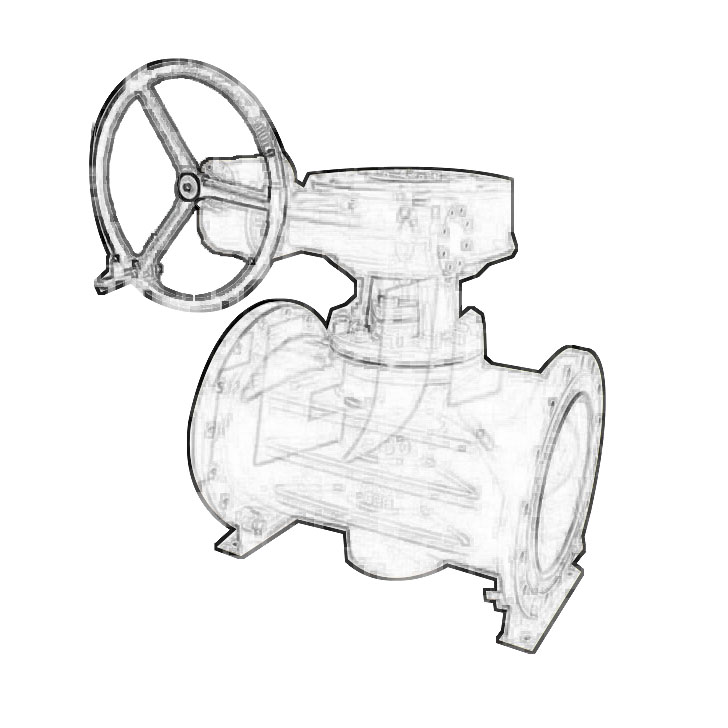

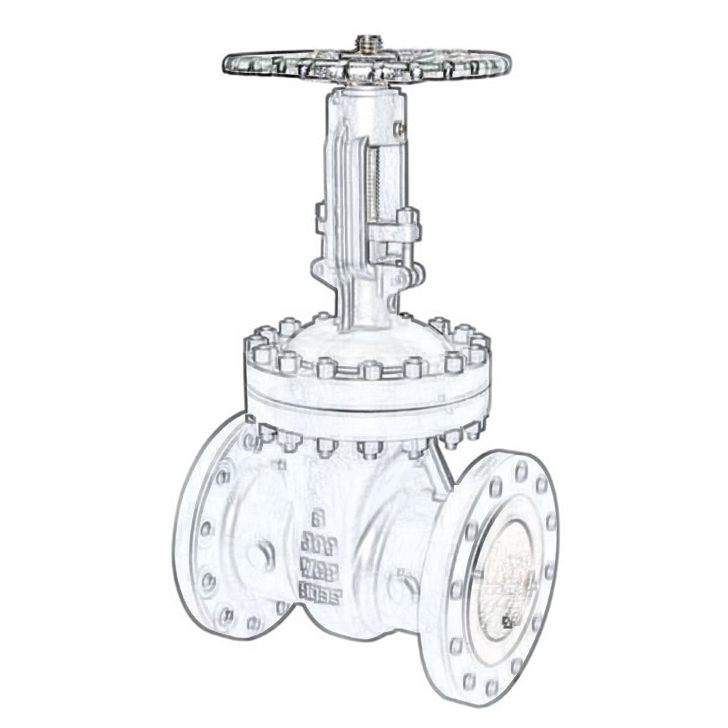

Product Detail

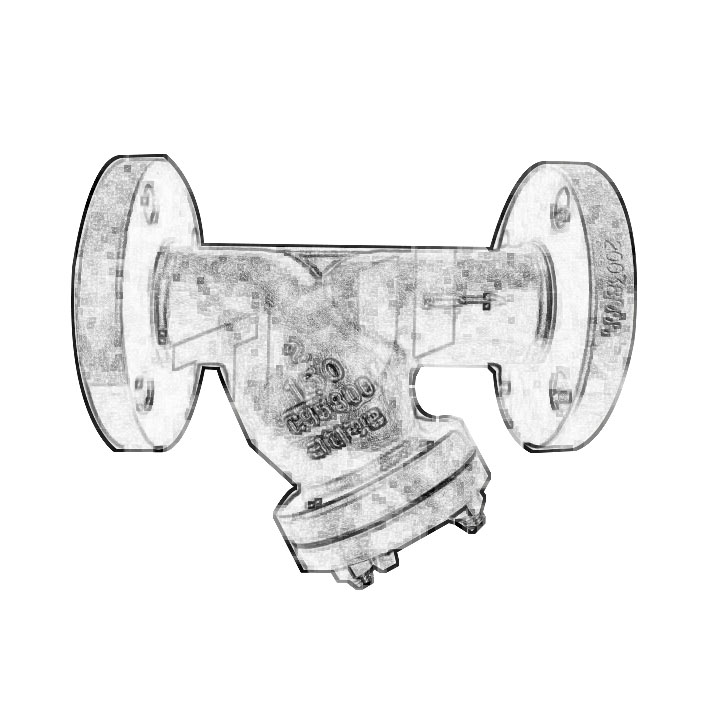

ANSI Cast Y-Strainer

Y-type strainers protect your fluid handling system against the damage that can occur to valves, traps and other equipment when foreign matter such as dirt, scale or welding particles travel through the pipeline. Available with Butt Welded or Flanged end connections in Carbon Steel,Stainless Steel,Bronze or Cast lron;for services up to 1480 PSI.

- category :Y Strainer

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

Y-type line strainers protect your fluid handling system against the damage that can occur to valves, traps and other equipment when foreign matter such as dirt, scale or welding particles travel through the pipeline. Available with Butt Welded or Flanged end connections in Carbon Steel, Stainless Steel, Bronze or Cast Iron; for services up to 1480 PSI.

Strainers feature a machine-tapered seat for a perfect fit of the removable strainer screen; and a blow-off plug that can be replaced with an optional ball valve for inline blow down of dirt, scale, etc. Selected sizes are in stock and ready for immediate delivery.

Y-Strainers take their name from their configuration. Y-Strainers are devices for mechanically removing unwanted solids from liquids, gas or steam lines by means of a perforated or wire mesh straining element. Y-strainers are very cost effective straining solutions in many applications, where the amount of material to be removed from the flow is relatively small, resulting in long intervals between screen cleanings. The strainer screen is manually cleaned by shutting down the line and removing the strainer cap.Stainless steel Y-strainers are used where high corrosion resistance or where freedom from contamination is required. They are popular in the chemical, food and pharma industries.

· Easy cleaning without interrupting the process.

· Various perforations, mesh or perforation mesh combinations are available to meet your process requirements.

· Can be installed either in a horizontal or vertical position.

|

Valve Size: 2″~24″ |

|

Pressure Class: 150LB~600LB |

|

Materials: WCB,CF8, CF3, CF3M, CF8M, C95800, Brass |

|

Design and Manufacturing Standards: ASME B16.34 |

|

Face to Face Standards: ASME B16.10 |

|

Flange Dimension Standards: ASME B 16.5, ASME B16.47 |

|

Pressure Test Standards: API598 |

|

Fire Safety Test Standards: API 607 |

|

Quality/Product Certifications: ISO9001,ISO14001,ISO18001 |

|

NACE: NACE MR 0103 / NACE MR 0175 |

|

Shut off Class: API 598 (Zero Leakage), API 6D |

|

Full Bore |

|

End Connection Type: RF, BW |

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.