Product Detail

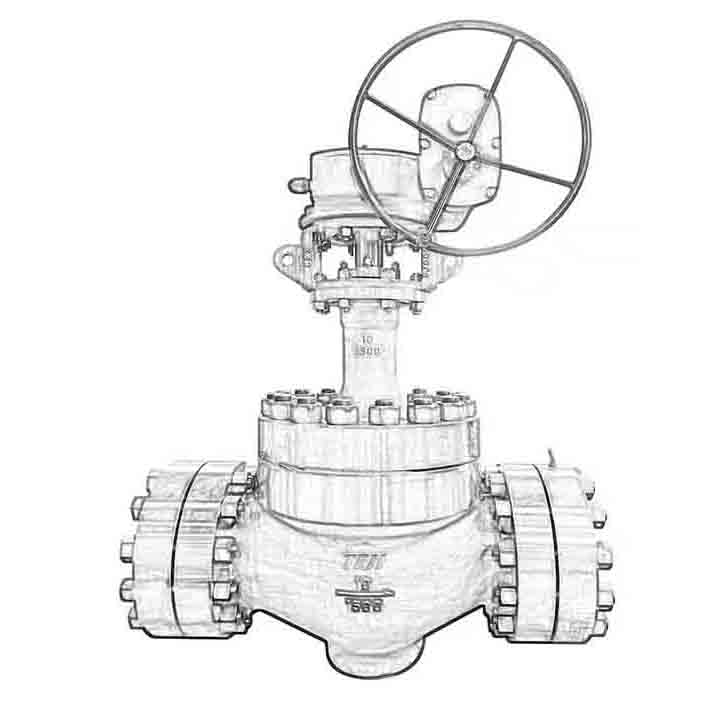

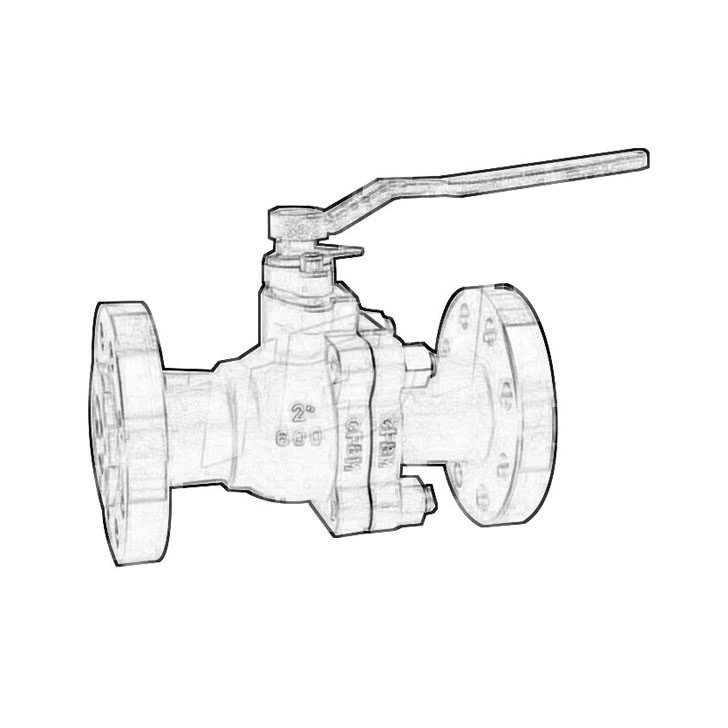

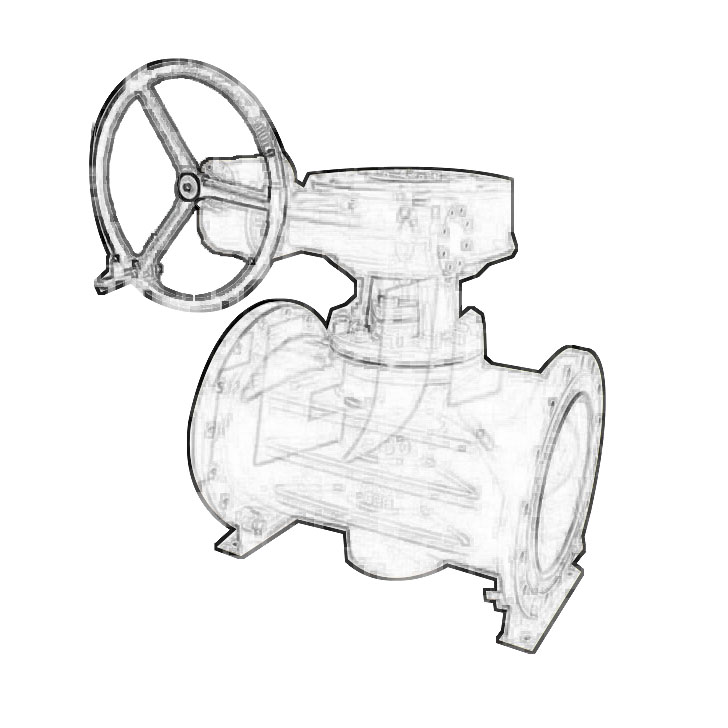

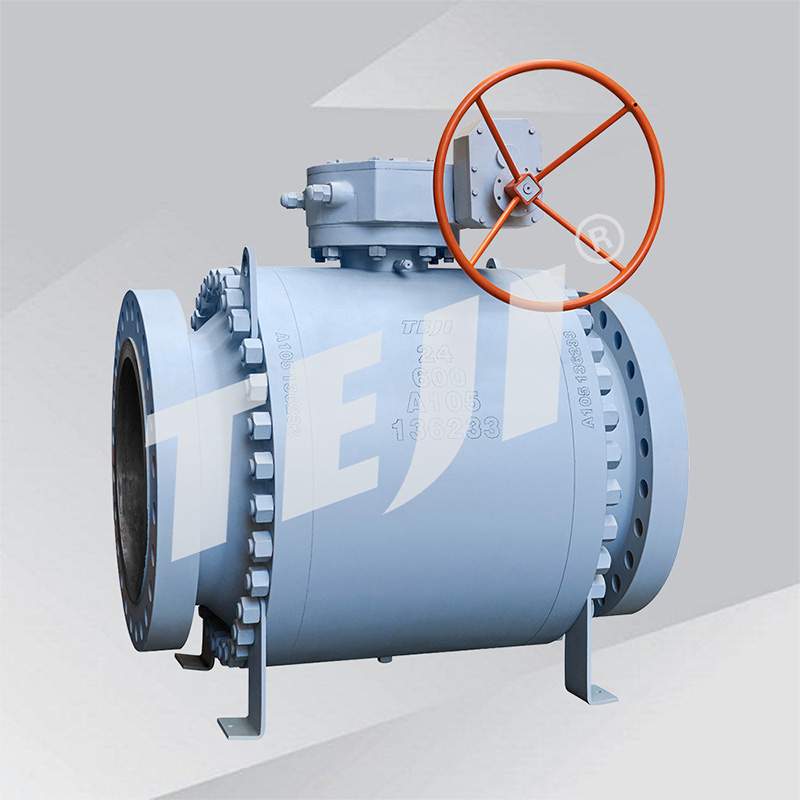

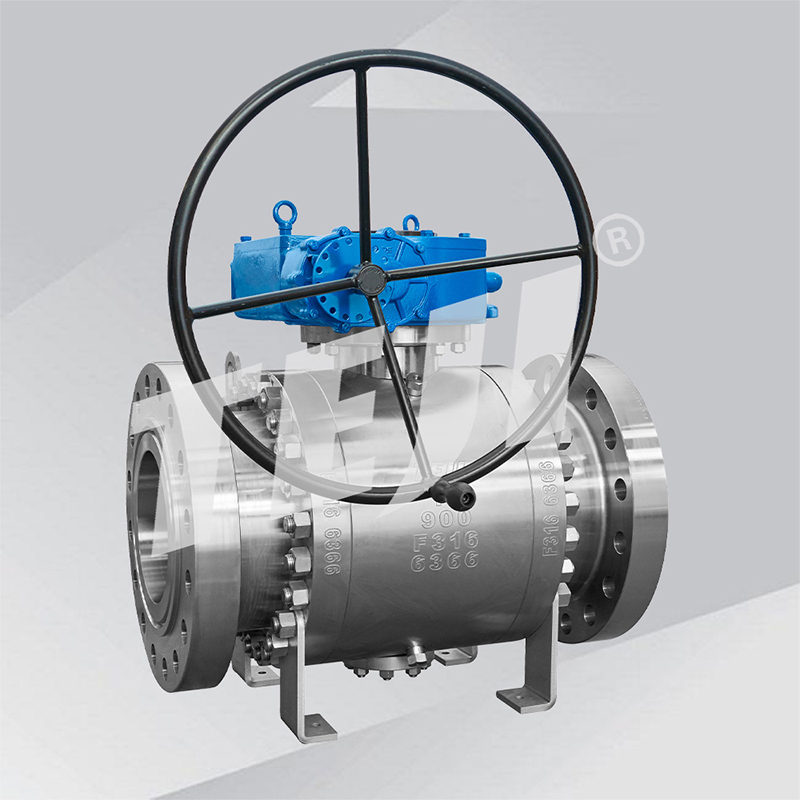

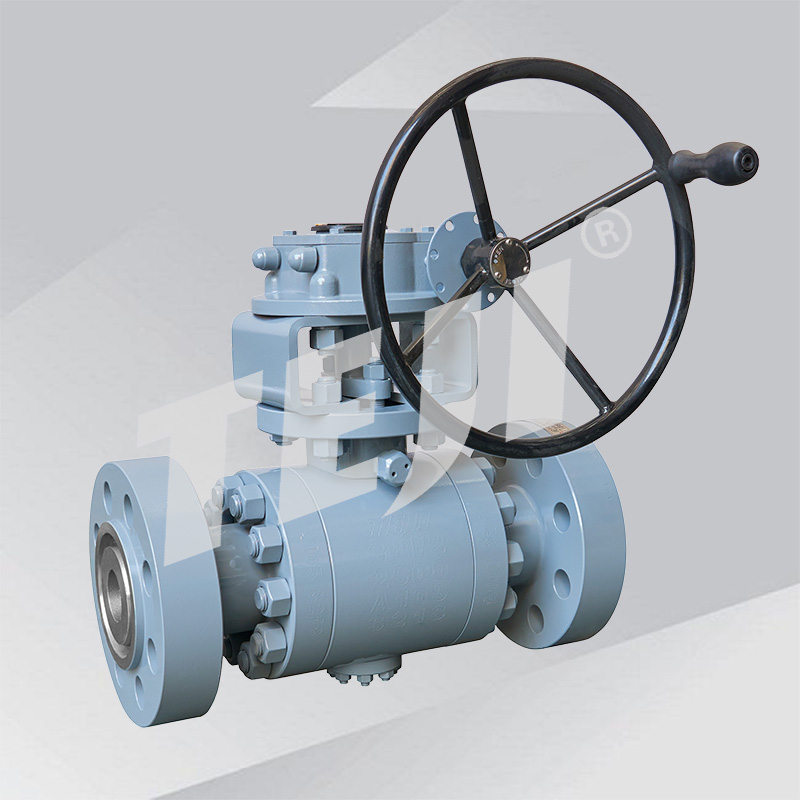

Forged Steel Trunnion Ball Valve

Trunnion ball valves have the obturator bounded by trunnion which prevents axial displacements of the ball itself in the flow direction.

- category :Turnnion Ball Valve

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

DESCRIPTION:

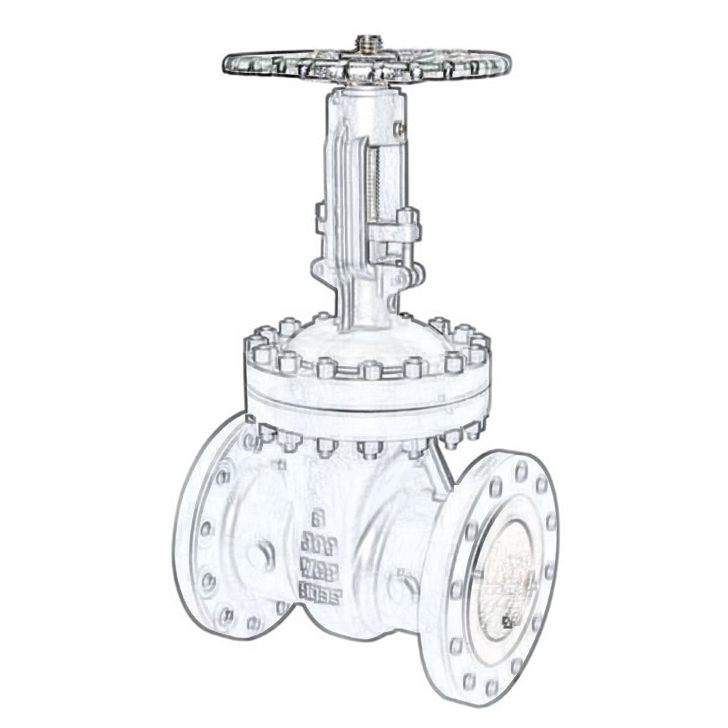

GENERAL CONSTRUCTION:

Trunnion ball valves have the obturator bounded by trunnion which prevents axial displacements of the ball itself in the flow direction; line pressure compresses the seat onto the ball, the contact between surfaces generates the valve sealing; trunnion standard construction ensure automatic cavity relief in case of overpressure in body cavity; these valves can be selected for a wide range of applications with no specific limits to all sizes and pressures.

Construction Two or Three piece bolted body

Port Reduced bore, full bore or fully piggable

Stem retention Anti blow-out stem

Leakage rate ISO 5208 rate A soft seated, rate D metal seated

Antistatic device Included, the ball valve design including an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function.

Pressure relief Automatic cavity relief to prevent over pressure in body cavity (self-relieving seats)

Bi-directional, Double block & bleed (DBB) with sealing in both directions (DIB-1&2 upon request)

Sealing Metal seated with Tungsten or Chrome Carbide coatings Primary metal secondary soft (PMSS) with different hardness between the ball and seat to prevent galling of the substrate Soft seated with thermoplastic polymers (Nylon, PEEK, PCTFE), special polymers upon request, Elastomers FKM, HNBR, EPDM O-Rings, special elastomers upon request.

Drain Drilled and threaded connections for all sizes

Vent Drilled and threaded vent connections for sizes≥DN150 (6") < DN150 upon request

Stem grease injectors Including for all sizes

Seat grease injectors Including for sizes≥DN150 (6"), < DN150 upon request

Lifting points Including for sizes ≥ DN150 (6") or on valves of 250 kg min.

Support feet Including for sizes ≥ DN150 (6") or on valves of 250 kg min

Stem extension Not foreseen for this model

Valve operation Lever, Gear box or Actuator with position indicator and locking device

Material testing Pressure containing & controlling parts to EN 10204 3.1

Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156

Non-destructive testing (NDT) to API 6D, ASME B16.34

Valve testing Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request)

TECHNICAL DATA:

Design: API 6D, API 6DSS, API 6A, ASME B16.34, ISO 14313, ISO 10423, ISO 17292

Design pressure: ASME B16.34, EN 1092-1, ISO 17292

Body wall thickness: ASME B16.34, ASME VIII Div. I, ISO 17292

Face to Face: API 6D, ASME B16.10 Long pattern

Temperature range: -29° to 200°C (-20.2° to 392°F)

Pressures range: PN20 (ANSI 150) to PN420 (ANSI 2500)

Size range: DN15 (1/2") to DN1400 (56")

End connections: ASME B16.5 ≤ DN600 (24") Flanged RF,FF,RTJ

MSS-SP-44 = DN550 (22") Flanged RF,FF,RTJ

ASME B16.47 A ≥ DN650 (26") Flanged RF,FF,RTJ

ASME B16.25 Butt-Weld BW

APPROVALS:

Safety Integrity Level: SIL 3

Fire Safe: API 607, API 6FA, BS 6755, ISO 10497-5

Area Classification: ATEX 94/9/EC

Pressure Equipment Directive: PED 97/23/EC

Fugitive Emission: ISO 15848/1

Construction: API 6D, API 608

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.