Product Detail

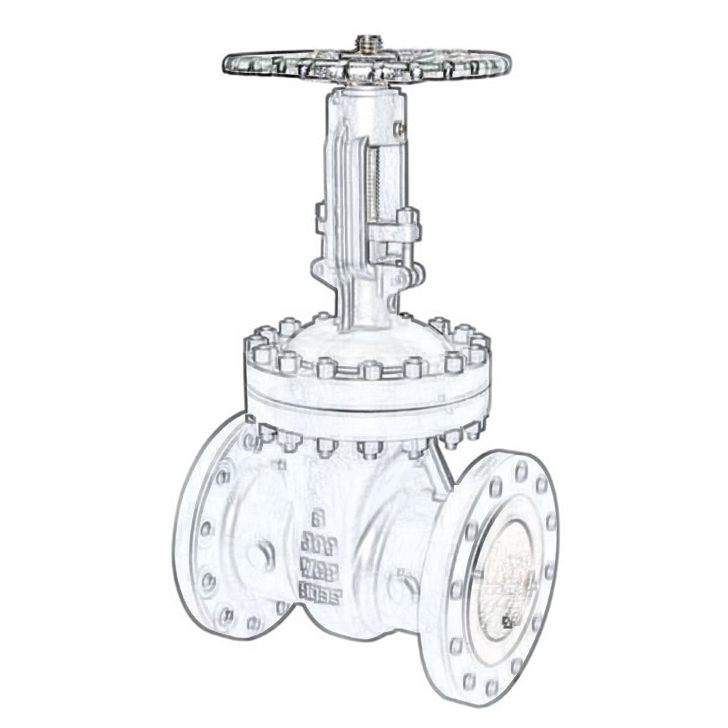

Forged Cryogenic Check Valve

Forged Cryogenic Check Valve is suitable for the pipeline where the medium flows in one direction to prevent the medium from returning to prevent accidents. And the working principle of Forged Cryogenic Check Valve is the same as that of Cast Steel Cryogenic Check Valve.

- category :Forged Cryogenic Valves

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

Forged Cryogenic Check Valve is suitable for the pipeline where the medium flows in one direction to prevent the medium from returning to prevent accidents. And the working principle of Forged Cryogenic Check Valve is the same as that of Cast Steel Cryogenic Check Valve. Mainly used in LO2, LN2, LAR, LNG, LC2H4, ethylene, liquid oxygen, liquid hydrogen, liquid nitrogen, liquid ammonia, liquid propane, liquefied natural gas, liquefied petroleum products and other systems to prevent medium backflow. It is suitable for methane, liquid natural gas, hexene, carbon dioxide, liquid ammonia, liquid oxygen, liquid nitrogen, liquid hydrogen and other cryogenic media.

PRECAUTIONS FOR FORGED CRYOGENIC CHECK VALVE:

1.Pay attention to the problem of valve body drainage and disk pressure relief. After the valve pressure test, the gas and moisture in the valve cavity of the sealed cavity will increase in pressure due to the increase in ambient temperature. When grease is injected, the pressure must be discharged first to facilitate the smooth progress of the grease injection.

2.After grease injection, the air and moisture in the sealed chamber are fully replaced out. Timely relief valve chamber pressure, but also to ensure the use of the valve safety. After grease injection, be sure to tighten the drain and pressure relief wire plug to prevent accidents.

3.Pls pay attention to the problem of uniform grease output when injecting grease. In normal grease injection, the grease outlet closest to the grease injection port first discharges the grease, then to the low point, and finally to the high point, and the grease is discharged one by one. If it shows unreasonable situation , proves there is a blockage, and clear it up in time.

SPECIFICATIONS:

1. Valve Size : 1/2” ~ 2”

2. Applicable Rating : ASME 150# ~ 1500#

3. Temperature : Down to -196 ℃

4. Designed : BS6364

5. Shell & Seat Leak Test : BS6364.

6. Constructions:

End Connection : Socket-Welded or Flanged Type

Full Bore/ Reduce Bore.

MATERIALS FOR MAIN PARTS:

|

PARTS NAME |

MATERIAL |

|

BODY |

Forged Steel - ASTM A182-F304(L)/F316(L) |

|

BONNET |

Forged Steel - ASTM A182-F304(L)/F316(L) |

|

SEAT |

ASTM A276-304(L) / 316(L)-(H.F) |

|

DISK |

ASTM A182-F304(L)/F316(L) |

|

STEM |

ASTM A276-304(L) / 316(L) |

|

GASKET |

SPIRAL WOUND GRAPHITE |

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.