Product Detail

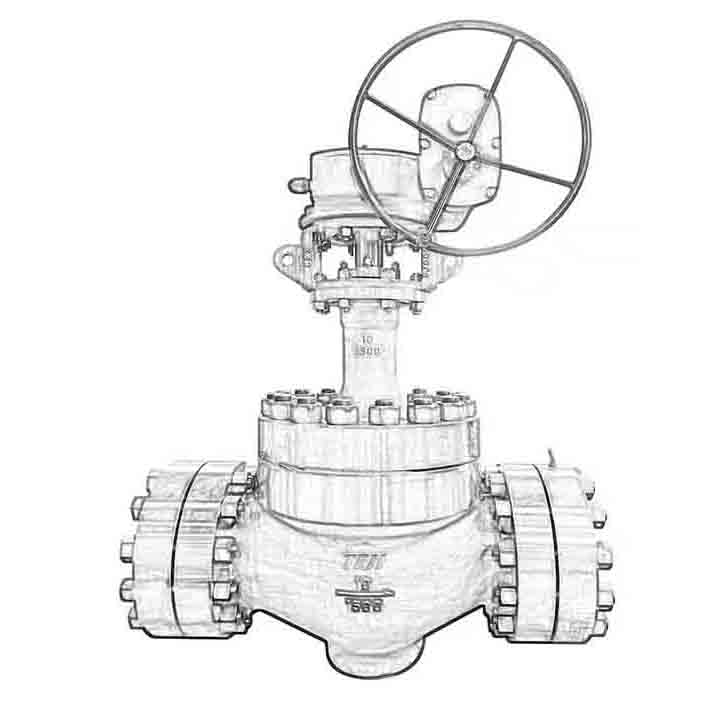

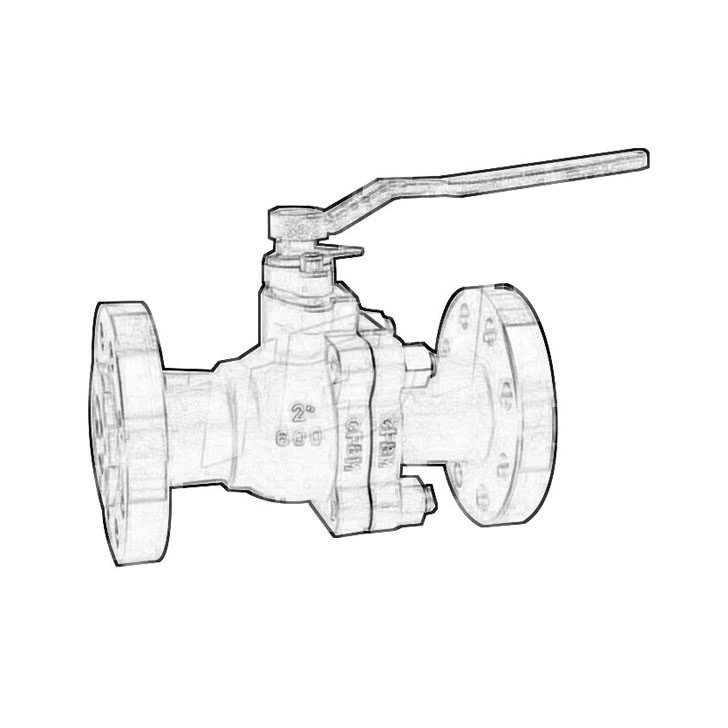

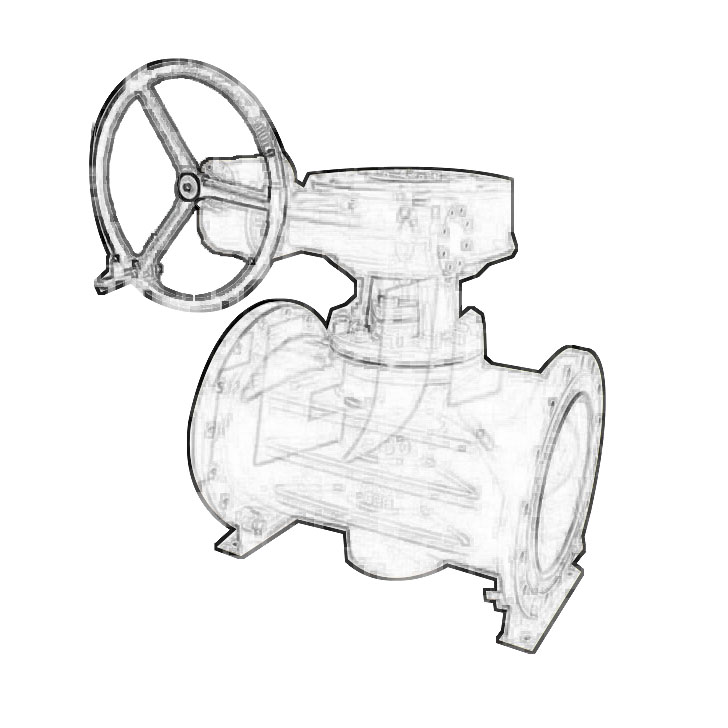

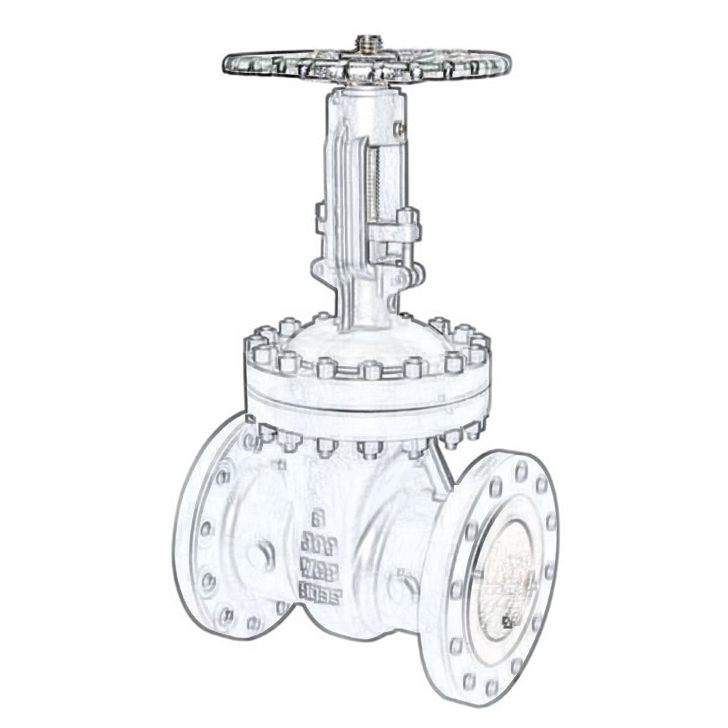

Cryogenic Split-Body Ball Valve

This ball valve can provide faster opening and closing movement and is suitable for storage tank applications as well as cryogenic pumps, pipelines or low-pressure trailers where leakage is "zero".

- category :Cryogenic Ball Valves

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

The flow diameter of the cryogenic ball valve is larger than that of similar globe valves. This ball valve can provide faster opening and closing movement and is suitable for storage tank applications as well as cryogenic pumps, pipelines or low-pressure trailers where leakage is "zero".Cryogenic ball valves are widely used in equipment including hydraulic gas, ethylene, and chemical engineering. With the development of related technologies, cryogenic ball valves have been widely demanded in many fields. The medium controlled by this valve has a cryogenic temperature, is toxic, flammable and explosive. Therefore, the cryogenic ball valve must maintain good performance in a relatively cryogenic temperature environment. According to the characteristics of the medium under cryogenic temperature conditions and related processing requirements, cryogenic ball valves maintain a special and specific design, manufacturing, inspection and installation methods that are different from ordinary ball valves.

SPECIFICATIONS:

1. Valve Size : 1/2” ~ 36” (Cast Steel) / 1/2” ~ 48” (Forged)

2. Applicable Rating : ASME 150# ~ 1500#

3. Temperature : Down to -196 ℃

4. Code & Standard : API, BS, ASME, ASTM

5. Constructions:

End Connection : Socket-Welded, Butt-Welded or Flanged Type

Long Extended Bonnet

Fire Safety Construction(Certified by TÜV)

Manual or Motor Operated (Pneumatic, Electric, or Hydraulic)

FEATURE:

1.All valve parts whose service temperature is less than -100°C shall be cryogenically treated in accordance with relevant regulations to prevent low-temperature brittleness of the material and volume change caused by phase change of the material at cryogenic temperature.

2.The long neck structure is adopted to make the packing work temperature above 0℃, effectively preventing the packing from reducing the sealing performance or even sealing failure due to the low working temperature, and it is convenient to wrap the valve with insulation material to prevent the loss of cold energy.

3.The floating ball valve adopts the inlet pressure relief outlet seal design, which effectively prevents the abnormal pressure rise in the middle cavity caused by temperature changes, and ensures the safe operation of the valve and pipeline.

MATERIALS FOR MAIN PARTS:

| PARTS NAME |

MATERIAL |

|

BODY |

Forged Steel - ASTM A182-F304(L)/F316(L) / Cast Steel - ASTM A351-CF8(M)/CF3(M) |

|

BONNET |

Forged Steel - ASTM A182-F304(L)/F316(L) / Cast Steel - ASTM A351-CF8(M)/CF3(M) |

|

SEAT |

PCTFE / GRAPHITE |

|

BALL |

ASTM A276-304(L) / 316(L)-(H.F) |

|

STEM |

ASTM A276-304(L) / 316(L) |

|

GASKET |

SPIRAL WOUND GRAPHITE |

|

GLAND PACKING |

GRAPHITE |

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.