Product Detail

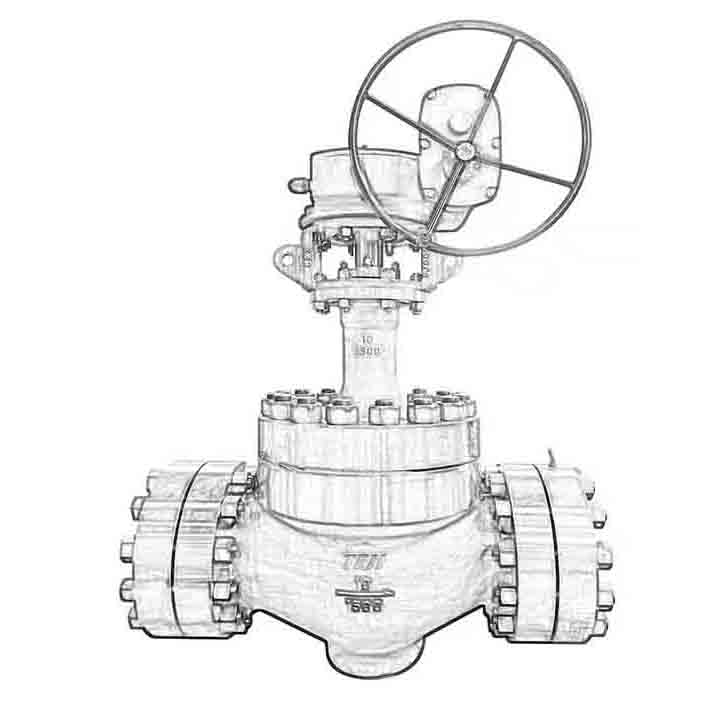

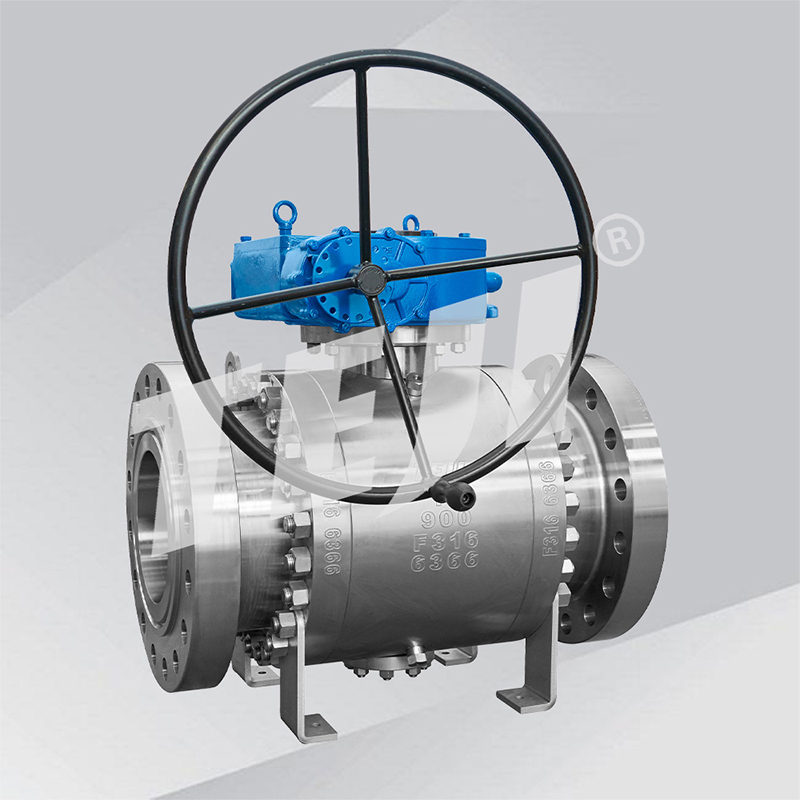

Forged Steel Trunnion Ball Valve

Trunnion ball valves have the obturator bounded by trunnion which prevents axial displacements of the ball itself in the flow direction.

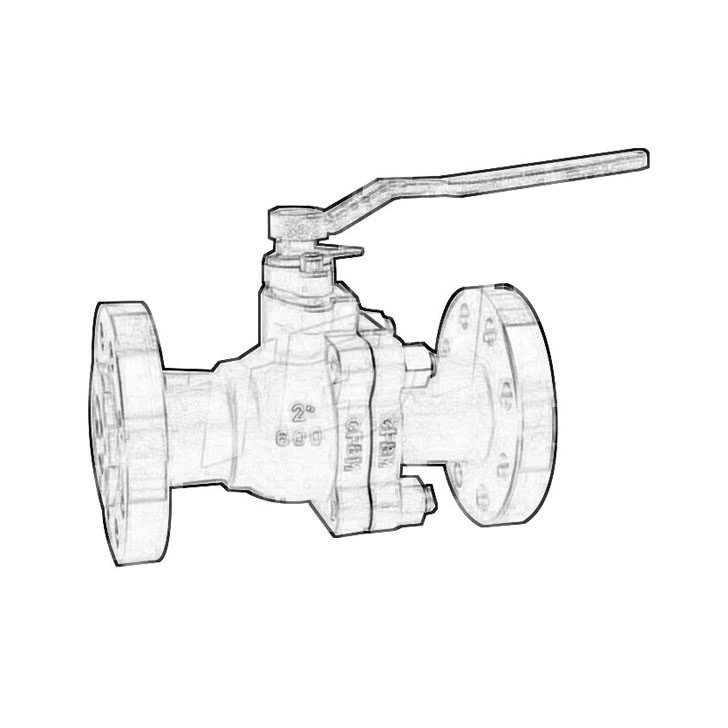

- category :Ball Valve

- Email :teji@teji-valve.com

- Phone :+86-577-67354000

- fax :+86-577-67354001

GENERAL CONSTRUCTION

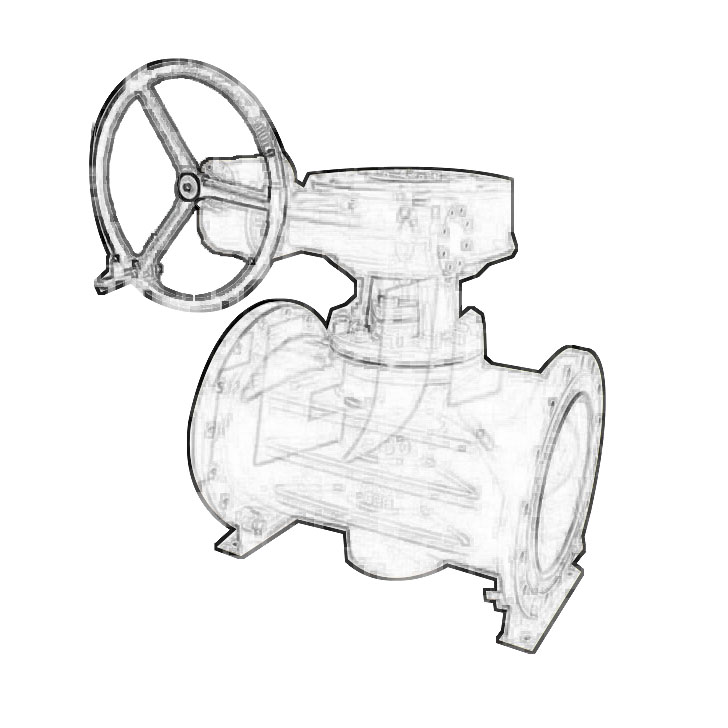

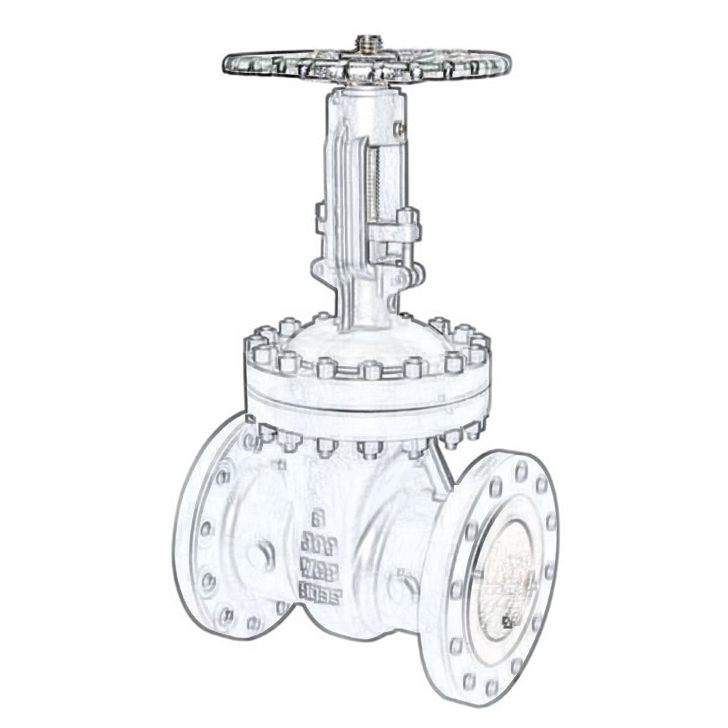

Trunnion ball valves have the obturator bounded by trunnion which prevents axial displacements of the ball itself in the flow direction; line pressure compresses the seat onto the ball, the contact between surfaces generates the valve sealing; trunnion standard construction ensure automatic cavity relief in case of overpressure in body cavity; these valves can be selected for a wide range of applications with no specific limits to all sizes and pressures.

|

Construction |

Two or Three piece bolted body |

|

Port |

Reduced bore, full bore or fully piggable |

|

Stem retention |

Anti blow-out stem |

|

Leakage rate |

ISO 5208 rate A soft seated, rate D metal seated |

|

Antistatic device |

Included, the ball valve design includes an electric conductive connection between the internal parts of the ball valve and the body, providing the anti-static function. |

|

Pressure relief |

Automatic cavity relief to prevent over pressure in body cavity (self-relieving seats) |

|

Sealing |

Bi-directional, Double block & bleed (DBB) with sealing in both directions (DIB-1&2 upon request) |

|

Drain |

Drilled and threaded connections for all sizes |

|

Vent |

Drilled and threaded vent connections for sizes ≥ DN150 (6") < DN150 upon request |

|

Stem grease injectors |

Included for all sizes |

|

Seat grease injectors |

Included for sizes ≥ DN150 (6"), < DN150 upon request |

|

Lifting points |

Included for sizes ≥ DN150 (6") or on valves of 250 kg min |

|

Support feet |

Included for sizes ≥ DN150 (6") or on valves of 250 kg min |

|

Stem extension |

Not foreseen for this model |

|

Valve operation |

Lever, Gear box or Actuator with position indicator and locking device |

|

Material testing |

Pressure containing & controlling parts to EN 10204 3.1 |

|

Valve testing |

Hydrostatic & pneumatic testing to API 6D, ASME B16.34, ISO 5208 (other upon request) |

TECHNICAL DATA

|

Design |

API 6D, API 6DSS, API 6A, ASME B16.34, ISO 14313, ISO 10423, ISO 17292 |

|

Design pressure |

ASME B16.34, EN 1092-1, ISO 17292 |

|

Body wall thickness |

ASME B16.34, ASME VIII Div. I, ISO 17292 |

|

Face to Face |

API 6D, ASME B16.10 Long pattern |

|

Temperature range |

-50° to 200°C (-58° to 392°F) |

|

Pressures range |

PN20 (ANSI 150) to PN420 (ANSI 2500) |

|

Size range |

DN15 (1/2") to DN1400 (56") |

|

End connections |

ASME B16.5 ≤ DN600 (24") Flanged RF,FF,RTJ |

APPROVALS

|

Safety Integrity Level |

SIL 3 |

|

Fire Safe |

API 607, API 6FA, BS 6755, ISO 10497-5 |

|

Area Classification |

ATEX 94/9/EC |

|

Pressure Equipment Directive |

PED 97/23/EC |

|

Fugitive Emission |

ISO 15848/1 |

|

Construction |

API 6D, API 608 |

Welcome to our website. If you have any requests or suggestions,please feel free to email us at teji@teji-valve.com or use the following enquiry form. Please allow us to provide you with the best service.